Printed Tag VS Chip

When selecting an RFID tag, a fundamental decision is whether to opt for a printed tag or a chip-based tag. Each type has its own strengths and weaknesses.

Printed Tags

Printed tags, also known as chipless tags, use conductive inks to create an antenna and encode data directly onto the tag material. They are typically less expensive to produce and can be integrated into various materials, such as paper or plastic. Printed tags are suitable for applications where low-cost, short-range tracking is required and where data storage needs are minimal. For instance, they can be used for event ticketing, product authentication, or item-level tagging in retail settings with low-value products.

Etiqueta Material Pressiza I09 Papel

Etiqueta Material Pressiza I05 Papel

Chip Tags

Chip-based RFID tags incorporate a microchip that stores data and an antenna to communicate with the reader. These tags offer greater data storage capacity, longer read ranges, and enhanced security features compared to printed tags. Chip tags are ideal for applications demanding higher levels of information, durability, and reliability. Industries such as supply chain management, healthcare, and asset tracking often rely on chip-based RFID tags to manage valuable items and track their movement with precision.

DogBone Inlay RFID Label

Zebra ZBR4000 Inlay RFID Label

Silverline Blade Inlay RFID Label

ShockWatch RFID

By understanding the key differences between printed and chip tags, you can select the most appropriate option for your specific needs.

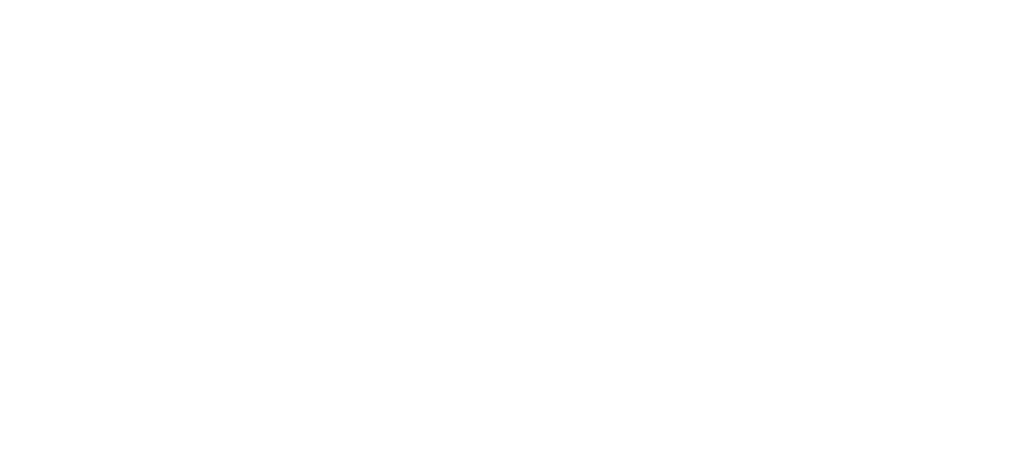

How to place RFID tags on your products and your packaging?

The placement of RFID tags is crucial for optimal read performance and accuracy. Here are some general guidelines:

Product Placement:

- Visible and Accessible: The tag should be placed in a location that is easily readable by RFID readers. Avoid placing tags in areas that may be obstructed by other products or packaging.

- Secure Adhesion: Ensure the tag is securely attached to the product to prevent detachment during handling or transportation. Consider using high-quality adhesives or other fastening methods.

- Avoid Metal Interference: If possible, avoid placing the tag near metal components that can interfere with the RFID signal.

Packaging Placement:

- External Visibility: For cartons or boxes, place the RFID tag on an external surface to maximize read range.

- Central Location: Position the tag in a central location on the packaging to improve read consistency.

- Avoid Obstructions: Ensure the tag is not covered by labels, barcodes, or other materials that may block the RFID signal.

Remember that the optimal placement may vary depending on the specific product, packaging material, and RFID technology used. It’s essential to conduct thorough testing to determine the best location for your application.

By following these guidelines, you can maximize the effectiveness of your RFID implementation and improve data accuracy.

Learn more about RFID solutions

Lior Rubin

RSI Mexico Strategic Partner