Custom adhesive labels

How it works: Custom adhesive labels are printed on a variety of materials with pressure-sensitive adhesive backing. This allows them to adhere to a surface with light pressure and stay securely in place. The design of the label can be completely customized, including size, shape, color, text, and graphics.

Applications: Custom adhesive labels have a wide range of uses across various industries. Here are two examples:

Label Material Pressiza 13 Fluorecent paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 23 Silver Paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 24 Gold Paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 106 Paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 108 Paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 121 Paper

Home 5/5 Details Related industries Technical sheet Quote...

Manufacturing industry

- Product Labels: Custom labels are essential for product branding and information. They display logos, product names, descriptions, ingredients, barcodes, and other critical details. (e.g., labels on food packaging, clothing tags)

- Promotional Stickers: Eye-catching custom stickers can be used for marketing campaigns, giveaways, or loyalty programs. They can be placed on packaging, windows, or products themselves. (e.g., seasonal sale stickers, limited edition product decals)

Healthcare Industry

Prescription Labels: In Mexico, pressure-sensitive labels are the primary method for displaying crucial information on prescription medication bottles. These labels adhere securely to the container and include details like patient name, medication name and dosage, doctor’s instructions, and potential side effects. Following NOM-070-SSA1-2016 regulations, these labels ensure clear communication and patient safety.

Medical Device Labels: Pressure-sensitive labels are essential for proper labeling of medical devices in Mexico. As dictated by NOM-137-SSA1-2024, these labels provide critical information like device name, manufacturer details, intended use, sterilization instructions, and safety warnings. The pressure-sensitive nature allows for secure adhesion to various device surfaces.

Promotional labels

Label 8000T Primary label for blood bag

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 03C Polypropylene Liner Transparent

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 03 Polypropylene

Home 5/5 Details Related industries Technical sheet Quote...

8000T Image Lock Label

8000T Checkerboard Gloss Silver Label

Home 5/5 Details Related industries Technical sheet Quote...

How it works: Promotional labels are a type of custom adhesive label specifically designed to grab attention and promote a product, brand, or service. They utilize eye-catching designs, colors, and messaging to entice customers. These labels can be temporary or permanent, depending on the desired use case.

Applications: Promotional labels are a versatile marketing tool used in various industries. Here are two examples:

Retail Industry

- New Product Launches: Promotional labels can be placed on existing products to announce new launches or highlight special features. They can also be used on packaging to create excitement and encourage customers to try the new offering. (e.g., “New and Improved” labels, “Limited Edition” stickers)

- Sales and Discounts: Eye-catching promotional labels can advertise discounts, special offers, or clearance sales. These are strategically placed on products or shelves to grab attention and drive sales. (e.g., “50% Off” stickers, “Buy One Get One Free” decals)

Manufacturing Industry

8000T Slide Label

Label Material Pressiza 13 Fluorecent paper

Home 5/5 Details Related industries Technical sheet Quote...

Label Material Pressiza 23 Silver Paper

Home 5/5 Details Related industries Technical sheet Quote...

- Trade Show Giveaways: Promotional labels can be placed on branded merchandise or giveaways distributed at trade shows. This creates brand awareness and helps generate leads. (e.g., Logo stickers on water bottles, Company name decals on tote bags)

- Product Warranties and Guarantees: Promotional labels can be used to highlight product warranties or guarantees, building customer trust and confidence in the brand. (e.g., “Lifetime Warranty” seals, “Money Back Guarantee” stickers)

Thermal labels

Indicadores de temperatura de alimentos

Indicadores de temperatura para envíos

Indicadores de temperatura sanguínea

Indicadores de congelamiento

Indicadores de calor TransTracker

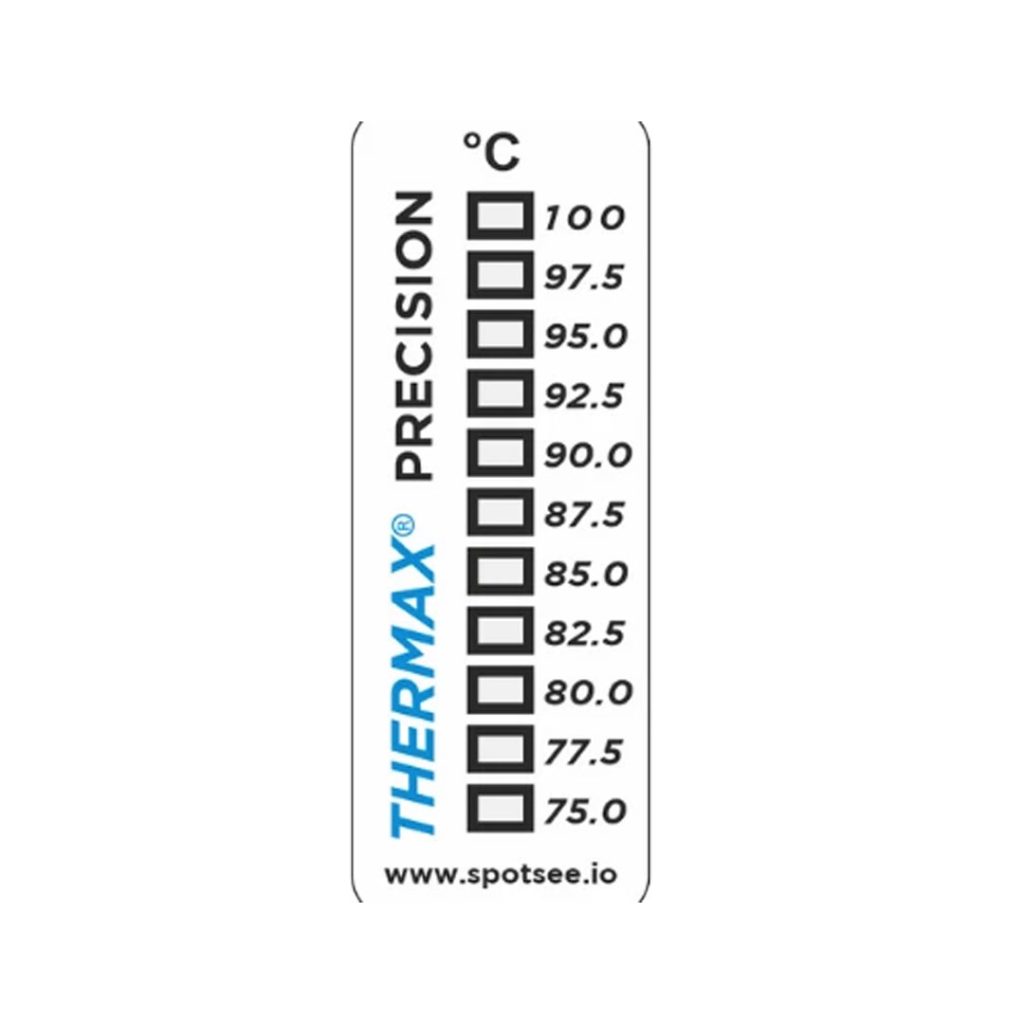

THERMAX PRECISION TEMPERATURE INDICATOR

How it works: Thermal labels are a specific type of custom adhesive label that uses heat to create the image on the label. There are two main types: direct thermal and thermal transfer. Direct thermal labels have a heat-sensitive coating that darkens when exposed to the print head of a thermal printer. Thermal transfer labels use a ribbon with a wax-based ink that melts and adheres to the label when heated by the print head.

Applications: Thermal labels offer fast printing and are ideal for applications requiring variable data. Here are two relevant industry examples:

Manufacturing

Production Line Labels: Thermal labels are perfect for printing variable information like lot numbers, expiration dates, and barcodes directly onto products during the manufacturing process. This ensures accuracy and streamlines production workflows. (e.g., Labels on electronic components with serial numbers, expiry stickers on food items)

Distribution

Shipping Labels: Thermal labels are widely used in warehouses and distribution centers for printing shipping information directly onto packages. This eliminates manual labeling and expedites the shipping process. (e.g., Address labels with barcodes, fragile handling stickers)

Heat shrink labels

How it Works: Heat shrink labels are tube-shaped labels made from a special type of plastic called polyolefin. They are designed to shrink tightly around an object when exposed to heat. The labels come in various diameters to accommodate different wire or cable sizes. Here’s the process:

- The label is selected to match the diameter of the wire or cable.

- The label is slipped onto the wire or cable.

- Heat is applied evenly to the label using a heat gun or heat shrink tunnel.

- As the label shrinks, it conforms to the shape of the object, creating a tight and secure fit.

Applications:

Automotive Industry

- Wire Identification: Heat shrink labels are a popular choice in the automotive industry for identifying and organizing wires within a complex electrical system. They provide a clear and durable way to mark wires with information like circuit function, part number, or voltage.

- Component Labeling: Heat shrink labels can also be used to label various components within a vehicle, such as relays, fuses, and sensors. This helps with troubleshooting and maintenance.

Aerospace Industry

- Critical Component Labeling: Due to their durability and resistance to harsh environments, heat shrink labels are ideal for labeling critical components in aircraft. This ensures clear identification and traceability of parts for safety and regulatory purposes. (e.g., labels on engine components, wiring harnesses)

- Wire Protection: Heat shrink labels can also provide an extra layer of protection for wires and cables in aircraft. They can act as a barrier against abrasion, moisture, and chemicals, extending the lifespan of the wiring system.

Biodegradable labels

How It Works: Biodegradable labels are made from materials that can decompose naturally under the right conditions. Unlike traditional labels that linger in landfills, these labels break down into harmless organic matter by microorganisms. There are two main types of biodegradable labels:

- Compostable Labels: These labels are designed to break down completely in a compost environment. They are typically made from plant-based materials like sugarcane or corn starch and use certified compostable adhesives.

- Oxo-Biodegradable Labels: These labels contain additives that trigger them to break down into smaller plastic fragments when exposed to sunlight and oxygen. However, these fragments (microplastics) can still harm the environment and are not considered a sustainable solution.

Applications

Food and Beverage Industry

8000T Slide Label

8000D Jewelry Label

Home 5/5 Detalles Industrias relacionadas Ficha técnica Cotizar...

- Sustainable Packaging: Biodegradable labels are a more eco-friendly alternative to traditional labels for food and beverage packaging. They align with the growing consumer demand for sustainable products and reduce the environmental impact of packaging waste. (e.g., labels on fruit containers, compostable labels on coffee bags)

- Fresh Produce Labeling: Biodegradable labels are well-suited for labeling fresh produce like fruits and vegetables. They won’t leave any harmful residue on the product and can potentially be composted along with any scraps.

Service Industry

- Event Signage: Biodegradable labels can be used for temporary signage at events like festivals or conferences. Since they decompose naturally, there’s no need to worry about leftover waste after the event is over. (e.g., directional signs made with biodegradable labels, compostable wristbands with printed information)

- Product Labeling for Eco-Friendly Businesses: Businesses that emphasize sustainability can leverage biodegradable labels for their products. This reinforces their commitment to environmental responsibility and resonates with eco-conscious customers. (e.g., labels on cleaning products made from plant-based ingredients, biodegradable stickers for reusable shopping bags)

Security labels

Impact indicators ShockWatch RFID

Home 5/5 Details Related industries Technical sheet Quote...

Impact indicators TiltWatch RFID

Home 5/5 Details Related industries Technical sheet Quote...

SpotBot 4G Plus: Impact, Temperature, Humidity and Location Monitor

Home 5/5 Details Related industries Technical sheet Quote...

Impact indicators ShockWatch Clip

Home 5/5 Details Related industries Technical sheet Quote...

Impact indicators ShockWatch Tube

Home 5/5 Details Related industries Technical sheet Quote...

How It Works: Security labels are designed to deter tampering and ensure the authenticity of a product or document. They come in various forms, each with its own unique security features:

- Tamper-evident labels: These labels leave a visible residue or message (“VOID”) upon removal, indicating tampering has occurred.

- Holographic labels: These labels utilize holographic effects that are difficult to replicate, providing a visual cue for authenticity.

- Destructible labels: These labels tear or shred into small pieces when tampered with, making it impossible to remove them cleanly.

Applications

Pharmaceutical Industry

- Anti-Counterfeiting: Security labels are crucial in the pharmaceutical industry to combat counterfeiting. They help ensure patients receive genuine medication and protect them from the dangers of fake drugs. (e.g., tamper-evident seals on medication bottles, holographic stickers on packaging)

- Tamper Detection: Security labels can also be used to detect tampering with medical equipment or packaging. This helps maintain the sterility and integrity of critical medical supplies. (e.g., security void labels on sterile packaging, tamper-evident seals on IV bags)

Manufacturing Industry

- Warranty Validation: Security labels can be used to validate product warranties. If the label is tampered with, it becomes void, indicating the warranty may be invalid. (e.g., tamper-evident seals on high-value electronics)

- Asset Tracking and Security: Security labels can be applied to valuable assets within a manufacturing facility for tracking and security purposes. Destructible labels make it difficult to remove them without detection. (e.g., security labels on laptops, tamper-evident seals on access control panels)

Ribbon for printer

True Colours® i Series™ Print Ribbons

Ribbon premium extremadamente resistente a productos químicos

How It Works: While not technically a label itself, printer ribbons are a crucial element used in thermal transfer printing. These ribbons are made of a thin film coated with a waxy or resin-based ink. During the printing process, the print head of the thermal transfer printer heats up in specific areas, causing the ink on the ribbon to melt and transfer onto the label material. This creates a durable, high-quality image on the label.

Applications:

There are various types of printer ribbons formulated for different printing needs. Here are two main categories and their applications across industries:

Wax Ribbons: Made with a wax-based ink, these ribbons offer good print quality at an affordable price. They are ideal for short-term applications where labels won’t be exposed to harsh conditions.

- Retail Industry: Wax ribbons are commonly used for printing price tags, shelf labels, and other labels with a short shelf life. (e.g., weekly sale stickers, discount labels)

- Food and Beverage Industry: Wax ribbons can be used for printing labels on non-refrigerated food items with a short shelf life, like bakery products or snacks. (e.g., labels on bread bags, “Best Before” stickers on cookies)

Resin Ribbons: Resin ribbons utilize a resin-based ink that offers superior durability and resistance to chemicals, moisture, and abrasion. They are ideal for labels that need to withstand harsh environments or remain eligible for extended periods.

- Manufacturing Industry: Resin ribbons are used for printing durable labels on parts, equipment, and products that may be exposed to chemicals, solvents, or extreme temperatures. (e.g., labels on electronic components with serial numbers, warning labels on chemical containers)

- Automotive Industry: Resin ribbons are used for printing labels on automotive parts that need to withstand heat, grease, and other harsh conditions under the hood. (e.g., warning labels on car batteries, identification labels on engine components)

Ribbon wax

How It Works: Wax ribbons, a type of printer ribbon used in thermal transfer printing, are made with a thin film coated in a wax-based ink. During printing, the thermal transfer printer’s heated print head comes into contact with the ribbon. This heat melts the wax ink in specific areas, causing it to transfer onto the label material pressed against the ribbon. The result is a clear, cost-effective printed image on the label.

Applications:

Wax ribbons are ideal for applications where affordability and short-term legibility are priorities. Here are two industry examples:

Retail Industry

- Price Tags and Shelf Labels: Wax ribbons are a popular choice for printing price tags and shelf labels due to their cost-effectiveness. They are suitable for products with a short shelf life or those that are frequently repriced. (e.g., weekly sale stickers, discount labels)

- Promotional Stickers: Businesses often use wax ribbons to print eye-catching promotional stickers for marketing campaigns or giveaways. Since these stickers are typically temporary, the focus is on grabbing attention rather than long-lasting durability. (e.g., seasonal sale stickers, limited edition product decals)

Food and Beverage Industry

- Non-Refrigerated Food Labels: Wax ribbons can be used for printing labels on non-refrigerated food items like bakery products or snacks that have a short shelf life. Since these labels don’t need to withstand moisture or extreme temperatures, affordability is a key factor. (e.g., labels on bread bags, “Best Before” stickers on cookies)

Lior Rubin

Socio Estratégico RSI Mexico